Research & Development

Technology on a Global Level

Core Technology

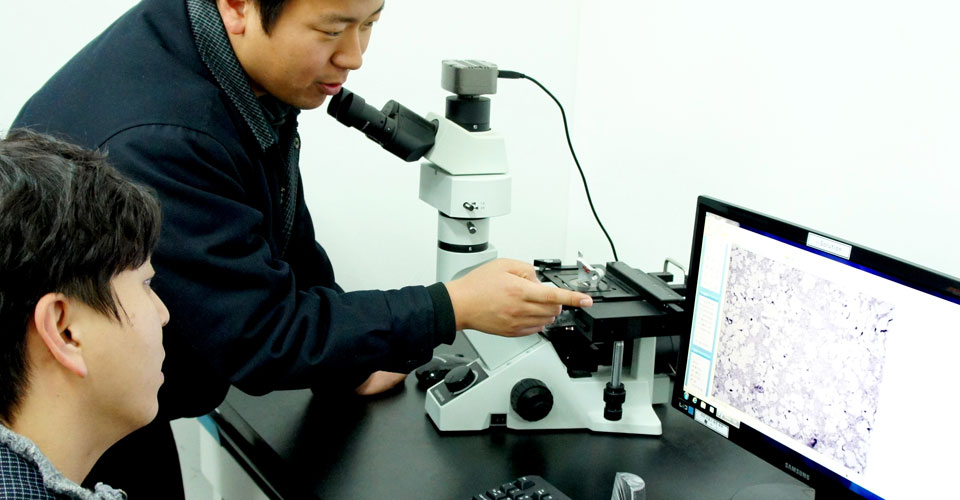

Since the establishment in 1988, our R&D center is the source of our technological leadership and innovation. Our R&D efforts are centered on materials research, casting technology, and process improvement, which are continuously applied to the manufacturing once validated.

We strengthened our expertise in materials by developing high-performance alloys, while conducting research on mechanical properties and castability, among others. Various computer-aided simulations and analyses contribute to advanced manufacturing technology and product quality. We achieved high level of production automation and flexibility with our robust team of engineers

Areas of Expertise

Development of Structural aluminum alloy

Research on grain refining and modification of aluminum alloy

Improvement of mechanical and thermal properties

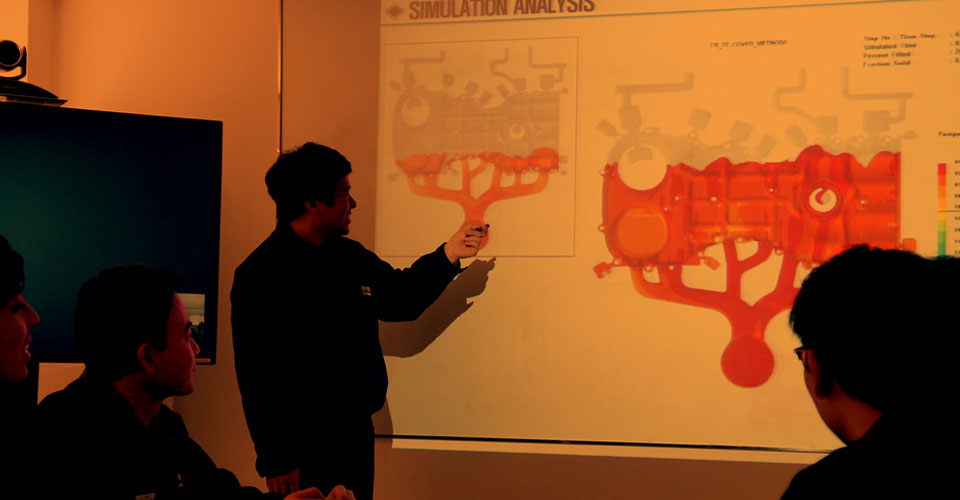

Optimization of gating system with filling and solidification simulation

Prediction of deformation by residual stress analysis

Optimization of parts ejection

Slurry casting technology for non-dendritic morphology

High-pressure vacuum die-casting

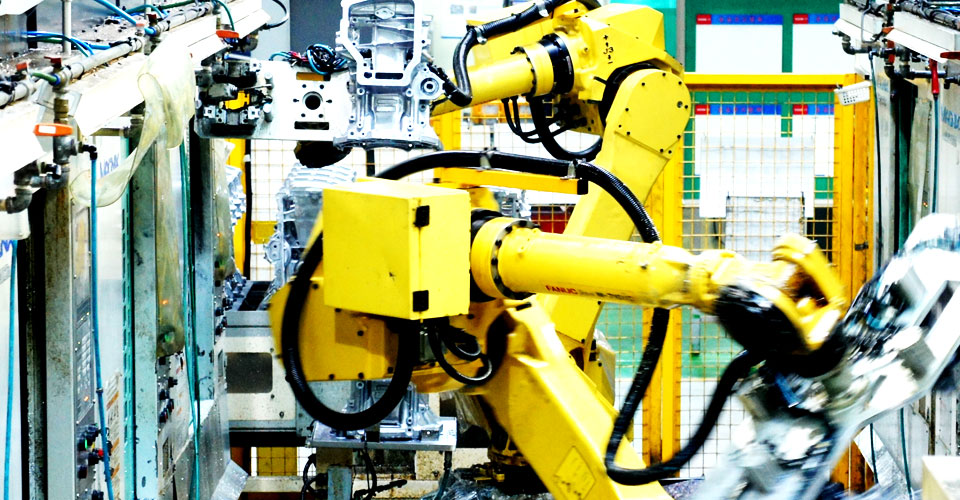

Automation of casting, machining and assembly systems

In-house design and development of jigs and fixtures

Process Engineering

Maximum Output on Minimal Input

We have robust in-house process engineering capability, which guarantees shorter lead time to and lower costs for series production by minimizing needs for turnkey equipment installations. Our process engineers focus on:

- Competitive, innovative process design

- Systems automation

- Layout optimization

- Equipment design, manufacture,

and application - Capex optimization

Also these are managed by analysis of feedback data from engineers and treated as critical skills in Samkee Automotive